Welcome to the official website of Dongguan Hongrui Hardware Technology Co., Ltd!

Dongguan Hongrui Hardware Technology Co., Ltd

Tel : 0769-89193593

Fax : 0769-89221086

Q Q : 1430123581

Mobile : 18666860579 Mr.zhang

Mobile : 13925799157 Ms.Cao

Address: Shenshan Industrial Zone, Hengli Town, Dongguan City, Guangdong Province

Website : www.hongrui59.com com

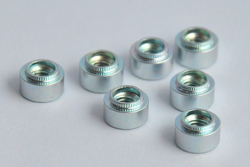

A brief introduction to rivet nuts

The rivet nut, as the name suggests, is a product that is fixed by riveting. It is a nut suitable for thin plates. Because of its small size, compact structure and convenient equipment, it is deeply loved by the public. Let Wansheng rivet nut manufacturer briefly introduce the rivet nut for you.

Pressure riveting nuts, also known as pressure riveting studs or pressure riveting nuts, are mostly used for riveting of PCB boards, circuit boards and various sheet metals, chassis, cabinets, etc. Production generally uses 1215 free-cutting steel and SUS303 stainless steel. With the gradual popularization of industry applications, some carbon steel rivet brackets are produced with 1008 cold pier wire.

Generally speaking, the most commonly used material on the market is iron. Iron one is called carbon steel. It is flushed or turned. The color is natural after production. To prevent rust, electroplating is necessary. Stainless steel rivet nuts do not require plating. As far as iron is concerned, the color of electroplating is generally determined by the customer, and the color of electroplating depends on what color the customer needs. There are also some requirements for salt spray time. Some electroplating colors have a long salt spray time, and some have less rust after a few hours of electroplating. Another point is to see whether customers need to export products. Generally, export products need to be environmentally friendly, and some domestic products also need it, but most of them do not.

Most of the electroplating used for rivet nuts on the market is environmental protection blue zinc, because the salt spray test time of environmental protection blue zinc can reach 72 hours, which is three days. The coating has a long salt spray resistance time. In fact, such as electroplating white nickel, the salt spray time of white nickel is relatively short, and it usually rusts in a few hours, less than 10 hours. However, some electroplating white nickel can be oiled, and the salt spray time of the rivet nut after oiling can be longer.

Rivet Nut Acceptance Test:

(1) Quenching crack of pressure riveting nut

1. Appearance characteristics: The crack is the grain cross section or along the grain boundary, and there will be obvious cracks along the foreign impurities. Cracks are usually caused by heat treatment or overstressing in forging or other forming processes. Heat treatment cracks often appear as rust and discoloration when objects are reworked.

2. Permissible range: cracks of any degree (depth, length) and location are not allowed.

(2) Forging cracks and impurity cracks of rivet nuts

1. Appearance characteristics: Forging cracks are generated on the top surface and corners of the nut head due to the operation of forging or cutting the blank. Impurity cracks are caused by the presence of metallic impurities or foreign objects in the material. Typical forging crack impurity crack pattern.

2. Allowable limit: If there are no more than two cracks from the hole to the edge, no cracks from the hole to the first tooth, and the crack depth does not exceed 0.5 times the tooth height, and the crack width does not exceed 0.02D or 0.012IN, the nut Forging cracks and chip cracks are allowed on the upper and lower surfaces.

(3) rivet nut locking crack

1. Appearance characteristics: The locking end of the rivet nut is compressed during the forming process, and cracks often appear near the locking end, and may also be typical locking end cracks on the inner edge or outer side.

2. Allowable limit: When the nut can pass the torsion test, the crack on the outer surface of the rivet nut is locked. Yes, if the nut can pass the torque test.

Copyright ©http://en.hongrui59.com/ Dongguan Hongrui Hardware Technology Co., Ltd Rivet nut,Press riveted stud,Rivet stud,Welcome to inquire!

Yue ICP Bei No. 15093989 Clouds platform Technical Support:HUASHANG NETWORK

Main business area: Dongguan Nanjing Xuzhou Shanghai Beijing Hebei Suzhou Shenzhen Jiangsu Wuhan